Links:

Black Annealed Wire: Crafting Functional Tools

Wall ties are typically made from materials like steel, plastic, or masonry, chosen for their durability and resistance to corrosion. They are installed horizontally at regular intervals throughout the height of the cavity wall, bridging the gap between the inner and outer layers. The choice of material and spacing of wall ties depends on factors such as the wall's height, width, and the environmental conditions it will endure. In the end, the snake realizes that its journey was not about finding answers, but about asking the right questions. The universe is an endless expanse of possibilities and mysteries, waiting to be explored and discovered. The snake's quest has not only transformed it into a being of unimaginable wisdom and understanding, but has also given it the courage to embrace the unknown and continue its journey into the vast cosmos. The Utility Extension Spring A Vital Component in Modern EngineeringAnnealed tie wire is specifically designed for tying applications. It is commonly used in construction to secure rebar and in agriculture for tying plants and vines. The annealing process gives this wire the necessary pliability to be easily twisted and tied without breaking, ensuring a strong and secure hold.

3. Install the Truss System Once the design is complete, the truss system can be installed by a qualified contractor. This typically involves attaching the beams or bars to the masonry walls or other load-bearing elements, using appropriate fasteners and anchors to ensure a secure connection.In the world of gardening, cages have long been a staple tool for supporting and protecting plants. However, traditional cages are often bulky, unsightly, and difficult to manage. That's where the small tomato cage comes in. This innovative product is designed to be compact, lightweight, and easy to use, making it an ideal choice for gardeners who want to grow tomatoes without sacrificing style or convenience. The installation of galvanized wall ties is a crucial step in the construction process. These ties are typically installed at regular intervals horizontally and vertically along the wall to provide maximum support. Proper installation is essential to ensure that the ties are securely fastened and able to withstand the weight and pressure of the walls.

Improve seismic performance: high-quality and suitable connectors help improve the seismic resistance of walls in natural disasters such as earthquakes and reduce the degree of damage.

Galvanized Iron Wire in Construction and Infrastructure

* Strength and Durability Welded mesh is incredibly strong and durable, making it an ideal choice for projects that require reinforcement. Despite their size, extra tall tomato cages are surprisingly easy to install and maintain. They can be placed around young seedlings or slipped over mature plants, with the flexibility to adjust as the plant grows. After the season, they can be easily dismantled and stored for reuse, making them an environmentally friendly and cost-effective gardening investment. The primary component of welded wire mesh sheets is steel wire, which can be either galvanized or made from stainless steel for enhanced corrosion resistance. The wires are cut to specific lengths and then joined together using an electric resistance welding process. This method ensures a strong, permanent bond, making the mesh resistant to deformation and able to withstand heavy loads. Wire mesh garden fences, typically made from steel or aluminum, offer a unique blend of durability and flexibility. Their robust construction ensures they can withstand harsh weather conditions, making them a reliable choice for garden boundaries. The mesh design allows air and sunlight to pass through freely, promoting healthy plant growth while still providing a level of privacy.Another advantage of stainless steel mesh is its corrosion resistance. Stainless steel is inherently resistant to rust, tarnish, and corrosion, making it suitable for outdoor and marine applications where exposure to moisture and harsh chemicals is common. This corrosion resistance ensures that stainless steel mesh maintains its structural integrity and appearance over time, reducing the need for frequent maintenance and replacement.

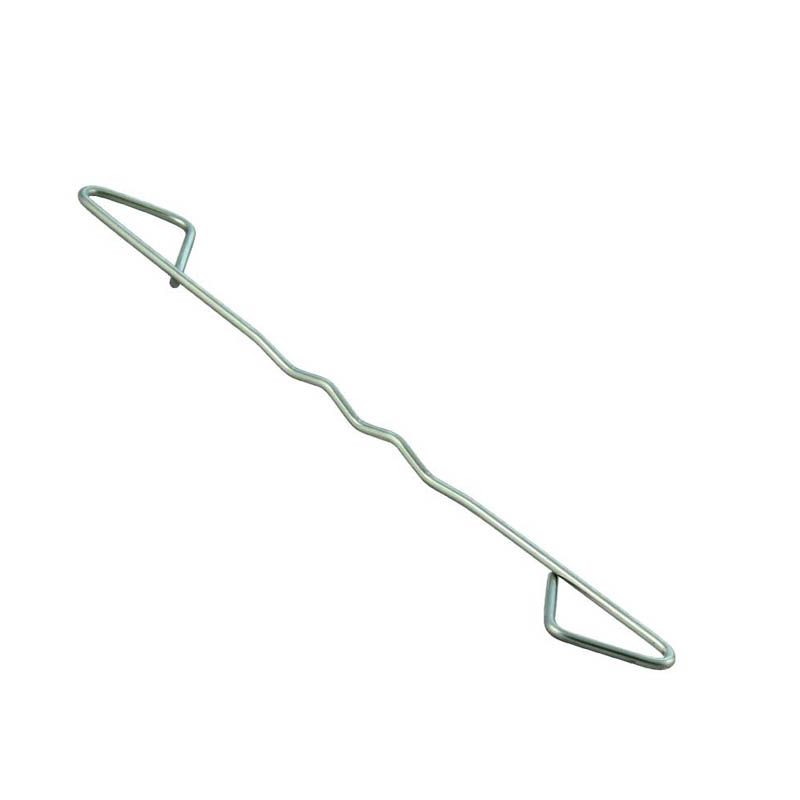

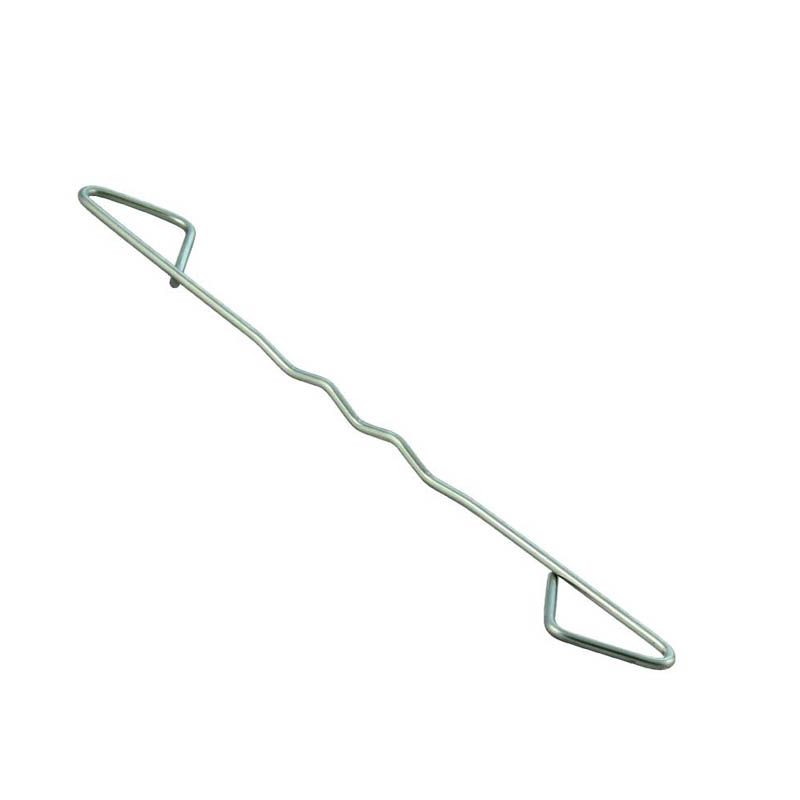

One of the great things about triangle wall ties is their versatility. They can be used in a wide range of applications, from restoring old buildings to enhancing new construction projects. Whether you're renovating a historic home or building a modern masterpiece, triangle wall ties are a versatile solution that can help you achieve your desired look while ensuring the longevity and stability of your walls. One of the key benefits of extending spring with %2212%\22 is the ability to enhance the framework's performance

12 extension spring. By adding optimized implementations of complex algorithms or introducing caching strategies, developers can significantly reduce the processing time for resource-intensive operations. For example, implementing a custom data access layer (DAL) using %2212%\22 can lead to significant improvements in application response times and scalability, especially when dealing with large volumes of data. In conclusion, plant cages and supports are essential tools for anyone looking to bring the beauty of nature into their home. By providing plants with the protection and support they need, you can create a thriving indoor garden that adds a touch of life and color to your living space. So why wait? Invest in a cage or support today and watch your plants flourish! When buying aluminum craft wire wholesale, it is important to find a reputable supplier that offers high-quality products. Look for suppliers that have a good reputation for their materials and customer service. You may also want to consider factors such as shipping times, return policies, and customer reviews when choosing a wholesale supplier. Size and quantity are also important considerations when determining the price of compression springs. Larger springs or springs with a higher load capacity will generally cost more than smaller springs. Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit

12 extension spring. By adding optimized implementations of complex algorithms or introducing caching strategies, developers can significantly reduce the processing time for resource-intensive operations. For example, implementing a custom data access layer (DAL) using %2212%\22 can lead to significant improvements in application response times and scalability, especially when dealing with large volumes of data. In conclusion, plant cages and supports are essential tools for anyone looking to bring the beauty of nature into their home. By providing plants with the protection and support they need, you can create a thriving indoor garden that adds a touch of life and color to your living space. So why wait? Invest in a cage or support today and watch your plants flourish! When buying aluminum craft wire wholesale, it is important to find a reputable supplier that offers high-quality products. Look for suppliers that have a good reputation for their materials and customer service. You may also want to consider factors such as shipping times, return policies, and customer reviews when choosing a wholesale supplier. Size and quantity are also important considerations when determining the price of compression springs. Larger springs or springs with a higher load capacity will generally cost more than smaller springs. Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit

Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit Additionally, purchasing compression springs in bulk can help reduce the overall cost per unit compression spring price. Manufacturers often offer discounts for larger orders, so it's important to consider your quantity needs when shopping for compression springs. Wide cavity wall ties are an essential component in the construction of masonry walls, providing stability and integrity to the structure. These ties are designed to bridge the gap between the inner and outer leaves of a cavity wall, ensuring that the walls remain rigid and resistant to wind and other forces. In this article, we will delve into the details of wide cavity wall ties, including their purpose, types, installation methods, and best practices for their use. Another advantage of using welded wire reinforcement is its ease of installation. The pre-fabricated grids can be quickly and easily placed within the concrete formwork, saving time and labor costs. This can be particularly beneficial for large-scale projects where efficiency is key. Wall ties are typically made from materials like steel, plastic, or masonry, chosen for their durability and resistance to corrosion. They are installed horizontally at regular intervals throughout the height of the cavity wall, bridging the gap between the inner and outer layers. The choice of material and spacing of wall ties depends on factors such as the wall's height, width, and the environmental conditions it will endure. Spring helical extensions find extensive use in industries due to their unique characteristics

compression spring price. Manufacturers often offer discounts for larger orders, so it's important to consider your quantity needs when shopping for compression springs. Wide cavity wall ties are an essential component in the construction of masonry walls, providing stability and integrity to the structure. These ties are designed to bridge the gap between the inner and outer leaves of a cavity wall, ensuring that the walls remain rigid and resistant to wind and other forces. In this article, we will delve into the details of wide cavity wall ties, including their purpose, types, installation methods, and best practices for their use. Another advantage of using welded wire reinforcement is its ease of installation. The pre-fabricated grids can be quickly and easily placed within the concrete formwork, saving time and labor costs. This can be particularly beneficial for large-scale projects where efficiency is key. Wall ties are typically made from materials like steel, plastic, or masonry, chosen for their durability and resistance to corrosion. They are installed horizontally at regular intervals throughout the height of the cavity wall, bridging the gap between the inner and outer layers. The choice of material and spacing of wall ties depends on factors such as the wall's height, width, and the environmental conditions it will endure. Spring helical extensions find extensive use in industries due to their unique characteristics Green Mesh Fencing Panels

Moreover, the cavity also provides a space for additional insulation materials, such as mineral wool or polystyrene beads, to be installed, further enhancing the wall's thermal performance Galvanised weld mesh sheets are a versatile and durable building material that is commonly used in construction, fencing, and industrial applications. These sheets are made from low carbon steel wire that is welded together at each intersection to create a strong and flexible mesh. The mesh is then coated with a layer of zinc to protect it from corrosion and rust. In addition to providing support for plants and creating barriers, 1.2mm garden wire can also be used for a variety of other tasks in the garden2mm garden wire can also be used for a variety of other tasks in the garden 2mm garden wire can also be used for a variety of other tasks in the garden2mm garden wire can also be used for a variety of other tasks in the garden

2mm garden wire can also be used for a variety of other tasks in the garden2mm garden wire can also be used for a variety of other tasks in the garden 1.2 mm garden wire. For example, it can be used to create decorative elements such as plant cages, sculptures, or even woven baskets. The versatility of garden wire makes it a valuable tool for any gardener looking to add a touch of creativity to their outdoor space.

1.2 mm garden wire. For example, it can be used to create decorative elements such as plant cages, sculptures, or even woven baskets. The versatility of garden wire makes it a valuable tool for any gardener looking to add a touch of creativity to their outdoor space. Extend the service life of the wall: A good connection can reduce the deformation and damage of the wall, thereby extending the service life of the entire cavity wall structure.

Plastering Corner Bead A Crucial Element in Drywall Construction The installation process begins with marking the positions for the wall ties. Generally, these should be placed at regular intervals, usually every 300-600mm horizontally and 450-600mm vertically from the floor. Use a spirit level to ensure they're evenly spaced. The Art and Significance of Brick Tie Detailing in Architectural DesignThe binding and baling of materials are essential processes in many industrial sectors, including manufacturing, recycling, and logistics. Galvanized iron wire is employed to securely bind together items such as cardboard boxes, bales of textiles, and bundles of waste products. The wire's high tensile strength allows it to withstand the pressure exerted by tightly packed materials, preventing them from coming loose or shifting during handling and transportation. This ensures that goods remain securely packaged, minimizing the risk of damage or loss during transit. Additionally, the corrosion-resistant zinc coating on the wire protects it from rust and degradation, even in harsh industrial environments, further enhancing its reliability and longevity.

6 Overall, hot-dipped galvanized iron wire is a versatile and useful material that has a wide range of applications. Whether you're looking to build a fence, reinforce a structure, or create a decorative piece, this type of wire is an excellent choice. Its durability, strength, and resistance to rust and corrosion make it a reliable and long-lasting option for any project. Thirdly, the manufacturing process is another crucial determinant. Welded mesh sheets go through a series of steps, including cutting, welding, and galvanizing. Advanced machinery and technology can improve efficiency, but it may also add to the initial investment, potentially reflecting in the final product price Advanced machinery and technology can improve efficiency, but it may also add to the initial investment, potentially reflecting in the final product price

Overall, hot-dipped galvanized iron wire is a versatile and useful material that has a wide range of applications. Whether you're looking to build a fence, reinforce a structure, or create a decorative piece, this type of wire is an excellent choice. Its durability, strength, and resistance to rust and corrosion make it a reliable and long-lasting option for any project. Thirdly, the manufacturing process is another crucial determinant. Welded mesh sheets go through a series of steps, including cutting, welding, and galvanizing. Advanced machinery and technology can improve efficiency, but it may also add to the initial investment, potentially reflecting in the final product price Advanced machinery and technology can improve efficiency, but it may also add to the initial investment, potentially reflecting in the final product price Advanced machinery and technology can improve efficiency, but it may also add to the initial investment, potentially reflecting in the final product price Advanced machinery and technology can improve efficiency, but it may also add to the initial investment, potentially reflecting in the final product price

Advanced machinery and technology can improve efficiency, but it may also add to the initial investment, potentially reflecting in the final product price Advanced machinery and technology can improve efficiency, but it may also add to the initial investment, potentially reflecting in the final product price weld mesh sheets prices. In the vast world of mechanical components and engineering, one particular type of spring that often finds its way into various applications is the extension spring. The term 1 8 extension spring might appear cryptic at first, but it holds a significant meaning in the context of spring design and manufacturing. Concrete Construction Accessories Enhancing Efficiency and Safety In the realm of horticulture, plant support plays a pivotal role in ensuring the healthy growth and robust development of various species. It is an essential aspect of garden maintenance that often goes unnoticed but significantly impacts the overall well-being of plants. Plant support refers to the use of physical structures or techniques to aid in the upright growth of plants, preventing them from collapsing under their own weight or environmental pressures. 7. Inspect and maintain Regularly inspect the cavity wall ties and the surrounding areas for any signs of damage or wear. If necessary, replace any damaged or worn ties to maintain the structural integrity of the building. In the realm of modern design, the white wire grid stands as an iconic symbol of minimalism and functionality. Its clean lines and simple structure evoke a sense of order and efficiency that is both aesthetically pleasing and practical in nature. This article delves into the significance of the white wire grid, exploring its various applications and the impact it has on contemporary design. In the context of a 2-inch compression spring, its relatively larger size makes it suitable for applications requiring higher force or more substantial deflection

weld mesh sheets prices. In the vast world of mechanical components and engineering, one particular type of spring that often finds its way into various applications is the extension spring. The term 1 8 extension spring might appear cryptic at first, but it holds a significant meaning in the context of spring design and manufacturing. Concrete Construction Accessories Enhancing Efficiency and Safety In the realm of horticulture, plant support plays a pivotal role in ensuring the healthy growth and robust development of various species. It is an essential aspect of garden maintenance that often goes unnoticed but significantly impacts the overall well-being of plants. Plant support refers to the use of physical structures or techniques to aid in the upright growth of plants, preventing them from collapsing under their own weight or environmental pressures. 7. Inspect and maintain Regularly inspect the cavity wall ties and the surrounding areas for any signs of damage or wear. If necessary, replace any damaged or worn ties to maintain the structural integrity of the building. In the realm of modern design, the white wire grid stands as an iconic symbol of minimalism and functionality. Its clean lines and simple structure evoke a sense of order and efficiency that is both aesthetically pleasing and practical in nature. This article delves into the significance of the white wire grid, exploring its various applications and the impact it has on contemporary design. In the context of a 2-inch compression spring, its relatively larger size makes it suitable for applications requiring higher force or more substantial deflection 2 inch compression spring. For instance, it could be employed in heavy machinery where robustness and durability are paramount. public byte[] decompressVideo(byte[] compressedVideo) throws IOException { In terms of applications, PVC Coated GI Binding Wire finds extensive use in construction projects, where it is employed for binding and reinforcing concrete structures. It is also commonly used in agriculture for securing fencing, trellising, and crop support. Furthermore, it plays a crucial role in the manufacturing of wire mesh, cable trays, and packaging materials. Its versatility extends to the electrical industry, where it serves as a reliable grounding wire. In the realm of industrial and architectural materials, black PVC coated wire mesh has emerged as a popular choice due to its durability, aesthetic appeal, and versatility. This innovative material combines the robustness of metal wire with the protective properties of polyvinyl chloride (PVC) coating, offering a range of benefits that make it suitable for various applications. The process of replacing bricks and ties is relatively straightforward but requires attention to detail and expertise. Skilled masons must carefully remove the damaged bricks and replace them with new ones, ensuring that the new bricks match the existing ones in terms of size, shape, and color. Ties must also be replaced to maintain the structural integrity of the structure. One way to save money on welded steel mesh is to purchase it in bulk Many leading wire mesh manufacturers in China are based in Hebei Province, particularly in cities like Anping, which is renowned as the Hometown of Wire Mesh due to its long history and expertise in this sector. These companies specialize in producing different types of wire mesh, such as stainless steel wire mesh, galvanized wire mesh, copper wire mesh, and more, catering to diverse industrial applications. Businesses too have harnessed the power of yard sign stands

2 inch compression spring. For instance, it could be employed in heavy machinery where robustness and durability are paramount. public byte[] decompressVideo(byte[] compressedVideo) throws IOException { In terms of applications, PVC Coated GI Binding Wire finds extensive use in construction projects, where it is employed for binding and reinforcing concrete structures. It is also commonly used in agriculture for securing fencing, trellising, and crop support. Furthermore, it plays a crucial role in the manufacturing of wire mesh, cable trays, and packaging materials. Its versatility extends to the electrical industry, where it serves as a reliable grounding wire. In the realm of industrial and architectural materials, black PVC coated wire mesh has emerged as a popular choice due to its durability, aesthetic appeal, and versatility. This innovative material combines the robustness of metal wire with the protective properties of polyvinyl chloride (PVC) coating, offering a range of benefits that make it suitable for various applications. The process of replacing bricks and ties is relatively straightforward but requires attention to detail and expertise. Skilled masons must carefully remove the damaged bricks and replace them with new ones, ensuring that the new bricks match the existing ones in terms of size, shape, and color. Ties must also be replaced to maintain the structural integrity of the structure. One way to save money on welded steel mesh is to purchase it in bulk Many leading wire mesh manufacturers in China are based in Hebei Province, particularly in cities like Anping, which is renowned as the Hometown of Wire Mesh due to its long history and expertise in this sector. These companies specialize in producing different types of wire mesh, such as stainless steel wire mesh, galvanized wire mesh, copper wire mesh, and more, catering to diverse industrial applications. Businesses too have harnessed the power of yard sign stands